Process

from tree to roots

At Vedic we believe the most precious gift from nature is the coconut tree and its by-products like coir pith and husk chips provide immense possibilities to regenerate soil. Our company focuses on the renewable, restorative and natural properties of coco products. We are dedicated in highlighting these benefits in order to help global growers reduce ecological impact. Below, you will find the steps our manufacturing partners take to craft nature’s raw materials into our exceptional products.

01

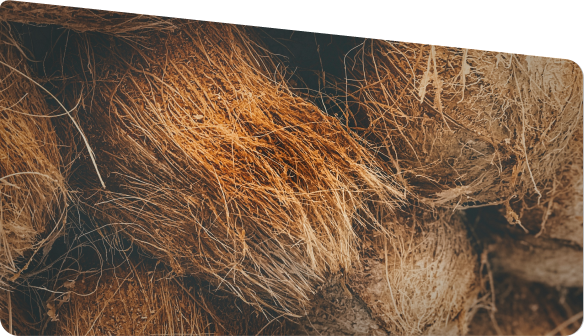

raw material

The raw materials are sourced from the traditional coconut tree growers. These raw materials are thoroughly checked for quality and only the best enters the warehouse for storing.

02

crushing

The specialized Coir Beater machine is where the raw coconut husks are broken down and the fibre is extracted using a beating principle.

03

PITH EXTRACTION

The Coir Beater takes the coconut husk pieces and separates the pith from the fibre. The machine’s outlet conveyor then extracts fresh coconut pith.

04

SCREENING

The extracted pith passes through the screener and it is tested by experienced staff to ensure only the highest quality move onto the manufacturing process.

05

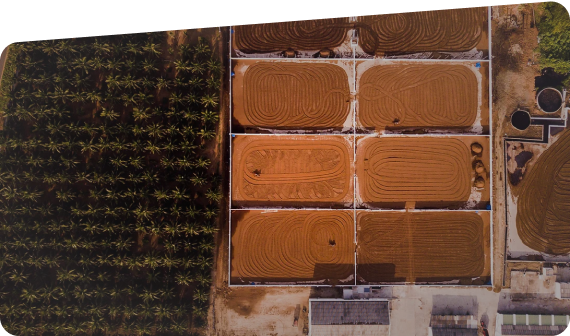

WASHING & EXTRA WASHING

Washing bunkers are used to reduce the default salt contents of the coir pith and extra washed to remove the excess elements. The extensive washing process, done through a specialized sprinkler system, continues over multiple weeks to reach accurate EC and pH values as per RHP standards.

06

DRYING

The washed pith is then naturally sun-dried in our large cement yards. The pith then moves through the advanced drying machine to ensure the material is free from all types of weeds and harmful pathogens.

07

COMPRESSING

Once the pith is dried, it is taken from the drying yards and fed into the compressing machines. In order to achieve highest efficiency for growers, the dried materials are compressed into 11.5 oz, 13 oz, 18 oz, 23 oz briquettes, 11 lbs. blocks or into compact grow slabs.

08

QUALITY CHECK

The compressed blocks then go through an intensive checking process. The quality control team helps deliver the very best by ensuring products are free from impurities like weeds, stones, sand, and pathogens.

09

PALLETIZING & SHIPPING

The compressed blocks are then packed into UV bags that are carefully arranged in disinfected wooden pallets to maintain hygiene levels. We use 40-foot high-cube containers or dry vans for transportation of products.

10

LOGISTICS & SHIPPING

The full containers then travel directly from the facilities by road and sea to reach our warehouses across the world.